Popular keywords: Deep groove ball bearing

The ball bearing has a cylindrical hole and a tapered hole structure, and the material of the cage is steel and synthetic resin. They are characterised by a spherical outer ring raceway with automatic adjustment, which can compensate for errors caused by different degrees of care and shaft deflection, but the relative tilt of the inner and outer rings must not exceed 3 degrees.

The raceway of the outer ring is spherical and its centre of curvature is the same as the centre of the bearing. Therefore, the inner ring, ball and cage can rotate freely around the centre of the bearing, with alignment. Suitable for shaft and shell to the centre of the difficult, shaft prone to deflection of the drive shaft and other applications. Because the contact angle is small, so the axial load capacity is also small. Generally use pressed cage.

Spherical ball bearings allow the adjustment angle, in the ordinary load case, about 0.07 ~ 0.12 radians (4-7 degrees). Depending on the relevant mounting dimensions around the bearing, there are special cases where this alignment angle cannot be achieved, so please note.

Sealed bearings with contact seals on both sides are available.

Series 22 and 23

Inner diameter 10 ≤ d ≤ 70 mm

Buna-N seals with steel skeleton (oil and wear resistant, type suffix 2RS1)

The permissible misalignment angle of sealed bearings is reduced compared to that of open bearings.

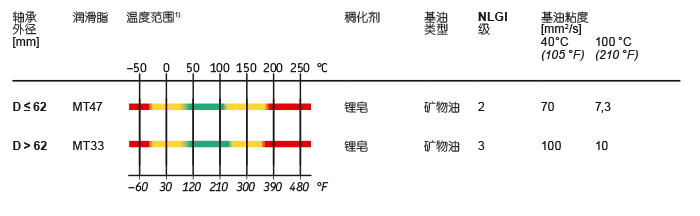

Grease for sealed bearings

Bearings with seals on both sides can be lubricated for life and are virtually maintenance-free. The bearings are pre-filled with the following standard greases with good corrosion resistance.

D ≤ 62 → MT47 Grease

D ≤ 62 → MT33 Grease

We want to hear your voice ~