Popular keywords: Deep groove ball bearing

Machine tool spindle refers to the axis on the machine tool that drives the workpiece or tool to rotate. The main shaft is usually composed of the main shaft, bearing and transmission parts (gear or pulley). In the machine, it is mainly used to support transmission parts, such as gears and pulleys, to transmit motion and torque, such as the machine tool spindle; Some are used for clamping workpieces, such as mandrels.

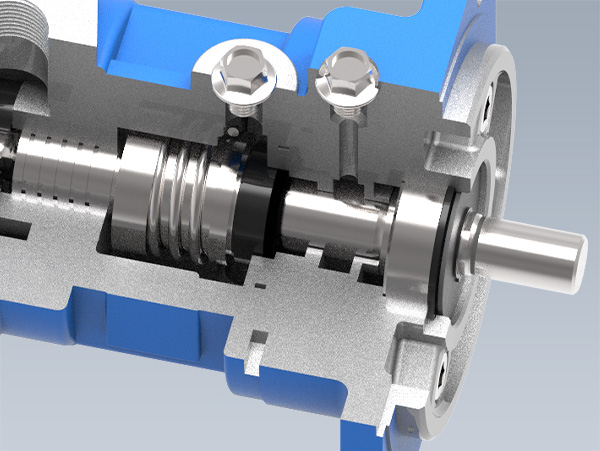

Machine tool spindle refers to the axis on the machine tool that drives the workpiece or tool to rotate. The main shaft is usually composed of the main shaft, bearing and transmission parts (gear or pulley). In the machine, it is mainly used to support transmission parts, such as gears and pulleys, to transmit motion and torque, such as the machine tool spindle; Some are used for clamping workpieces, such as mandrels. Except for planer, broaching machine and other machine tools whose main motion is linear motion, most machine tools have spindle parts. The motion accuracy and structural stiffness of spindle components are important factors that determine machining quality and cutting efficiency.

The main indicators to measure the performance of the spindle components are rotation accuracy, stiffness and speed adaptability.

① Rotation accuracy: the radial and axial runout in the direction that affects the machining accuracy when the spindle rotates, mainly depends on the manufacturing and assembly quality of the spindle and bearing.

② Dynamic and static stiffness: mainly depends on the bending stiffness of the main shaft, the stiffness and damping of the bearing.

A2-8-230 lathe belt coupling spindle

A2-8-230 lathe belt coupling spindle

③ Speed adaptability: the maximum allowable speed and speed range are mainly determined by the bearing structure, lubrication and heat dissipation conditions.